Your benefits

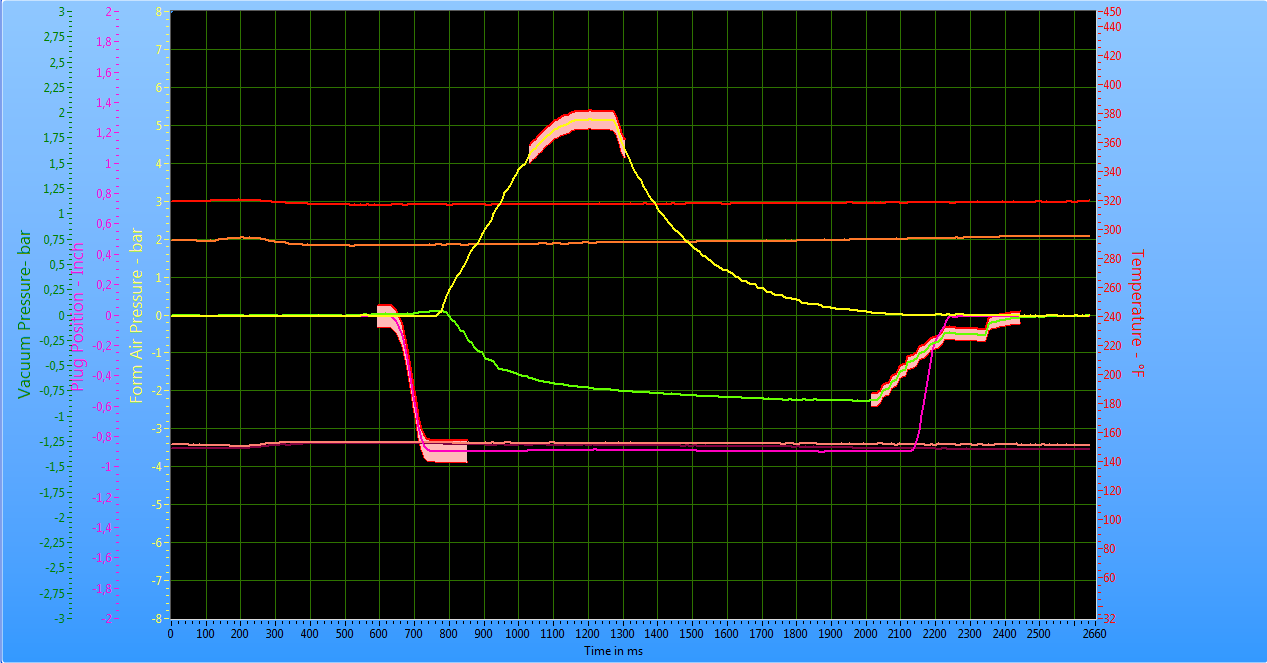

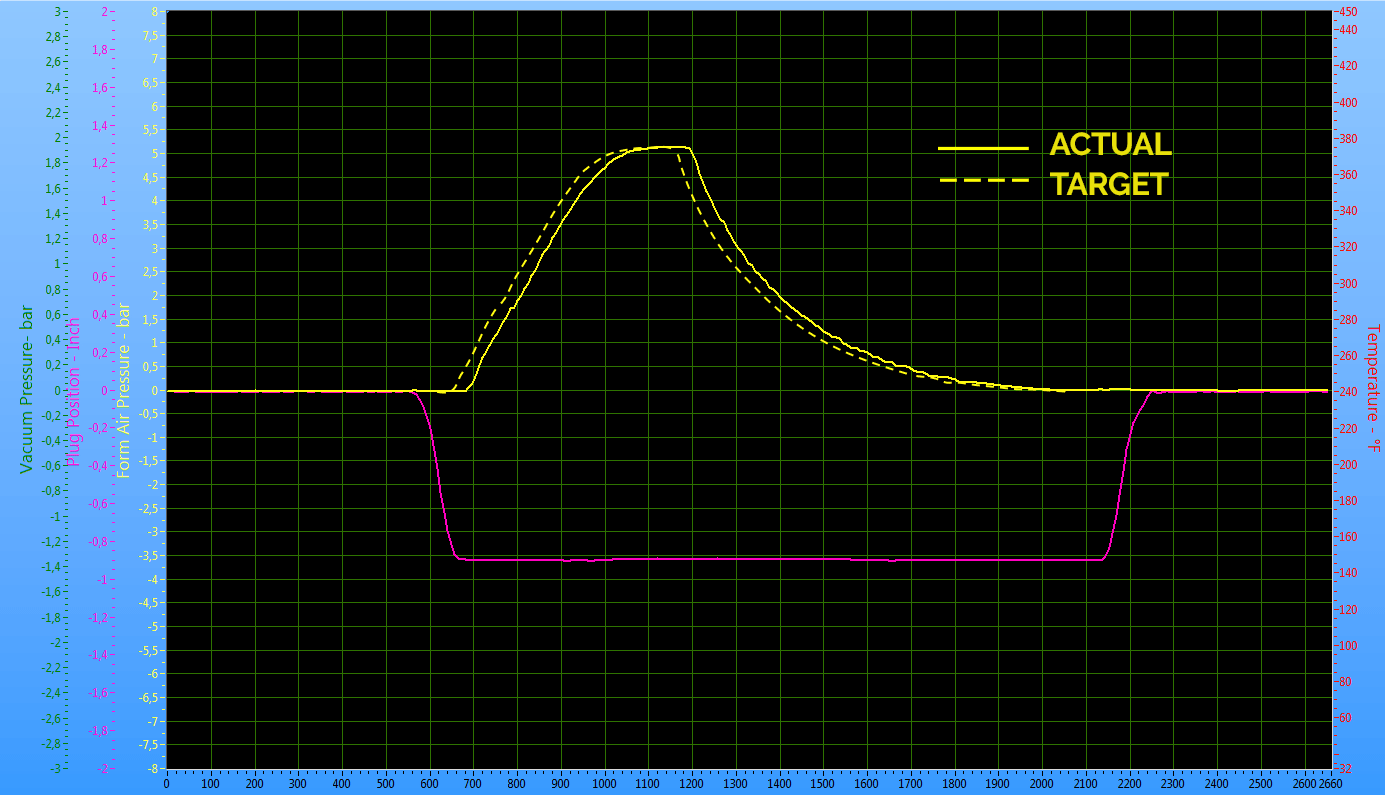

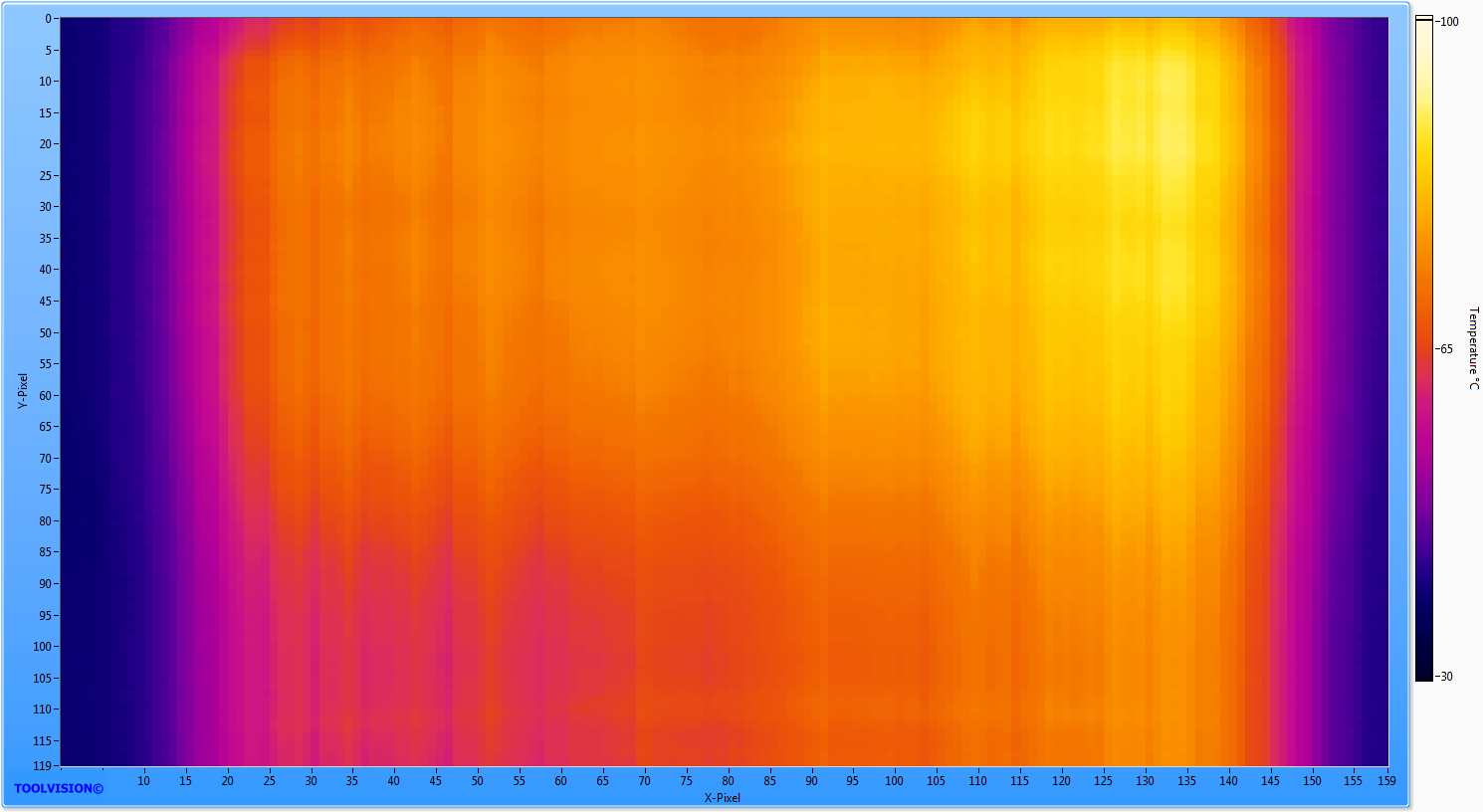

Process visualisation and continual real-time process monitoring

Documentation of the production run

Reduction of start-up waste by up to 50%

More production output and product stability

Save thousands of wasted units

Avoidance of post-production due to deficient quality